Statewide Services from the Lean Six Sigma Experts of Arizona

Contact Us

Lean Six Sigma is a globally recognized paradigm for changing systems and businesses sustainably and demonstrably. It proposes a system for enterprises to systematically generate concrete results (DMAIC, or Define, Measure, Analyze, Improve, and Control) while ensuring quality improvement. The first move is to highlight what customers like and incorporate it into processes. In this technique, costs are minimized, consumer loyalty is higher, and lead times are shortened. The beauty of this approach is that it draws on people’s previous knowledge and experience with the systems.

We use the Lean Six Sigma technique at Lean Six Sigma Experts of Arizona to improve both operation and performance. The aim of lean is to increase flow and value generation. Six Sigma strives for both robust and effective systems. When used together, they are fully complementary and strengthen each other.

What are the advantages of Six Sigma for Arizona’s businesses?

Any of the benefits of Six Sigma for companies are described below:

- Profitability is enhanced, and waste is eliminated.

- The customer’s attention has increased.

- Changes the company’s culture for the best in the long run.

- Establishes a plan of action and goals.

- Encourages learning and development in one’s life.

According to one study, any manufacturing or service business that performs badly costs a company a lot of money. In certain cases, that could account for close to half of a service organization’s budget. The results indicate that “productive work” accounts for less than 10% of the process cycle time. The remainder is made up of waste, rework, and other non-value-added operations.

In Lean Six Sigma, What Are The Different Roles?

System improvement is a difficult task. If the right people with the right Lean Six Sigma expertise are involved, a true and long-term transformation may be made. Karate is the root of the term “belts,” or “bands” in Dutch. The multiple skill levels are represented in this illustration. The most critical functions in Lean Six Sigma are as follows:

Yellow Belt: Has a foundational knowledge of the Lean Six Sigma approach. Procedure questions are dealt with by Green and Black Belts workers. Engages in project teams and receives on-the-job training Green Belt: Launch and maintain Lean Six Sigma projects. Has some Lean Six Sigma training, although not as many as Black Belts. Others will undergo JIT (just-in-time) training. Black Belt: Operates under the guidance of a Master Black Belt. Has vast Lean Six Sigma expertise. Act as a consultant, coach, teacher, and group chief for project teams. Master Black Belt: A Master Black Belt's job is to work with leaders to identify deficiencies and choose (improvement) initiatives. Act as coaches and mentors, some work as a teacher and oversees specific activities. In charge of a company's Lean Six Sigma implementation and culture change.

Yellow Belt

Green Belt

Black Belt

Master Black Belt

In Arizona, how can you successfully involve top management?

We want to hold an executive launch session with Lean Six Sigma Experts of Arizona to include senior management early in the implementation planning cycle. These meetings will be organized by the CEO or COO in collaboration with the deployment organizer and will provide direct presentations and key collaborators. A typical executive launch could increase visibility about how Lean and Six Sigma support the CEO’s priorities and enable senior team members to invest in Lean Six Sigma’s ability.

It will also provide the senior management team the ability to internalize the deployment approach, make decisions, and schedule core operational and managerial tasks and habits.

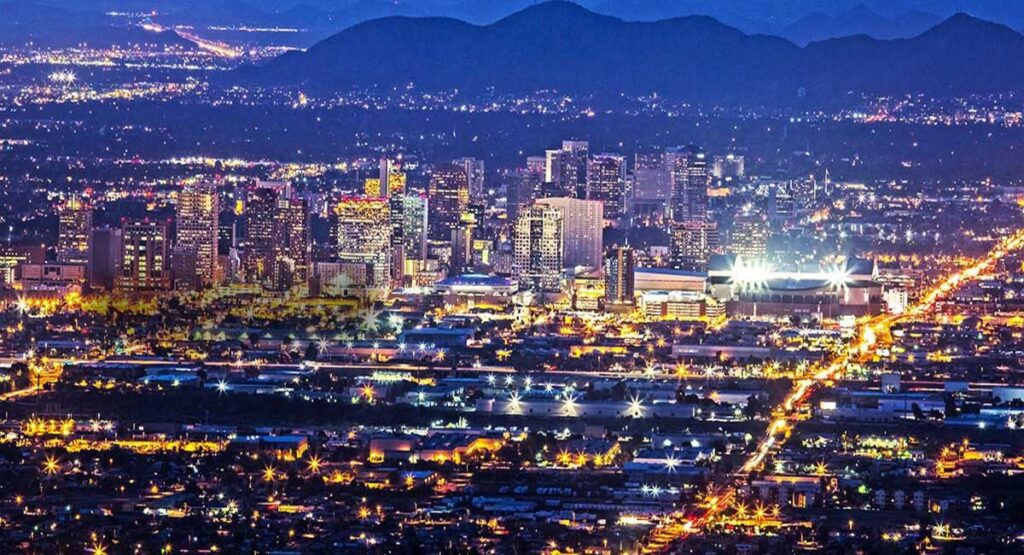

There are so many areas or regions where we offer these services with most of them being cities.

However, if you need any of these services, you need to contact us. The list below comprises the areas where we offer these services.